Extraction Equipment

Carbon dioxide and solvent (alcohol, ethanol, butane) extraction equipment is mainly used to extract pigments, oleoresins, plant proteins, essential oils, terpenes, and other natural compounds from natural resources.

Plant extraction technology

In recent years, the fast-developing plant extraction technologies include supercritical fluid extraction, ultrasonic extraction, wave dissolution, microwave-assisted extraction, high-speed countercurrent chromatography, solid phase extraction, solid phase microextraction, enzymatic extraction, semi-bionic extraction, and liquid membrane extraction. , Fast solvent extraction, etc. Especially in order to solve the adverse effects of solvents in traditional analysis, solvent-free or solvent-less sample extraction methods have developed rapidly.

What equipment is used for plant extraction?

Plant extraction refers to the use of physical, chemical, and biochemical principles and methods to isolate the effective ingredients from plants with high purity without destroying the structure and function of the effective ingredients.

There are approximately 500,000 higher plant species in the world, of which approximately 70,000 species are used for the production of plant-based medicines. Although there are many different applications like the active ingredients of vegetables, they all have one common feature: they are extremely sensitive substances and must be extracted through gentle biotechnological processes.

In the contemporary industry, the main types of extraction equipment are in use: CO2 extractors (supercritical and subcritical), steam distillation, and solvent extraction machines.

Plant extraction equipment

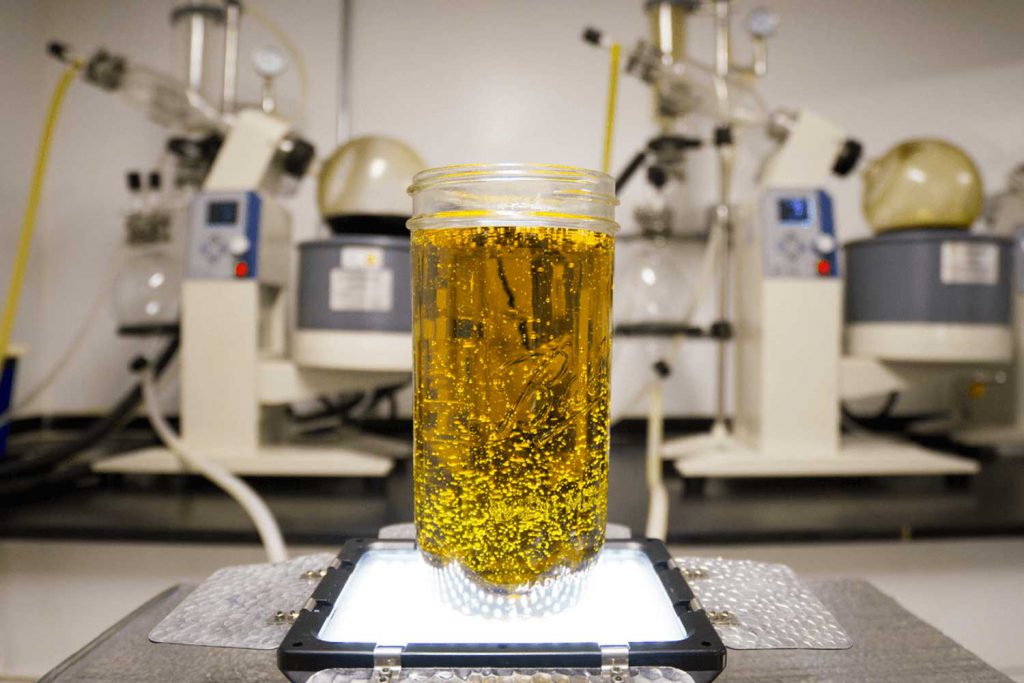

Plant extraction equipment, also known as extractors, is a type of mass transfer equipment used for extraction operations. It can make good contact between the extractant and the material liquid and realize the perfect separation of the components contained in the material liquid.

An extraction machine is applied in the plant extraction industry for extracting herbal essential oils, oleoresins, aromas, natural extracts, proteins, and active compounds from natural plants or herbs.

CO2 Extraction Machine

CO2 (Carbon Dioxide) is another popular solvent that is used for essential oils and terpene extraction. CO2 extraction requires pressurized CO2 (used as a solvent) to pull the essential oils, terpenes, and other compounds from plants. CO2 results in pure terpenoid isolate and is considered very safe.

CO2 as a solvent isn’t volatile and leaves no trace residue, which is why it’s so commonly used in food processing and to produce essential oils.

CO2 is also an excellent option for extracting fragile plant terpenes for high-quality distillates that maintain the flavor profiles of the original plant.

Hydrocarbon Extraction Equipment

Hydrocarbons are a category of organic compounds that only consist of hydrogen and carbon. They don’t contain any atoms other than hydrogen and carbon.

That leaves alkanes as the most useful type of hydrocarbons when extracting compounds from plant materials.

Currently, the most popular alkanes used for hydrocarbon extraction are:

- Butane (n-butane C4H10)

- Propane (2-methylpropane C4H10)

- or a blend of Butane or Propane

Steam Distillation Equipment

Steam Distillation is the most popular method used to extract and isolate essential oils from plants for use in natural products. This happens when the steam vaporizes the plant material’s volatile compounds, which eventually go through a condensation and collection process.

Distilling raw materials to obtain essential oils is a process that must be 100% mastered in order to guarantee a high-quality final product.

The choice of steam distillation equipment is a criterion to be examined in particular. It must be capable of extracting a high-quality essential oil while keeping energy consumption and the quantity of raw materials required to a minimum.

Steam extraction functions by passing steam through plant material which has been stored in a large holding tank or chamber, known as a “distillation column”. This allows for the essential oils to be extracted at a low temperature which will not damage the plant matter.

As the steam is released and passes through the organic plant material, tiny pockets which hold the essential oils will open and release the oil molecules into the air without causing any damage to the distillate.

The final result will consist of a mixture of water vapor and essential oils which will return to a liquid form when cooled.