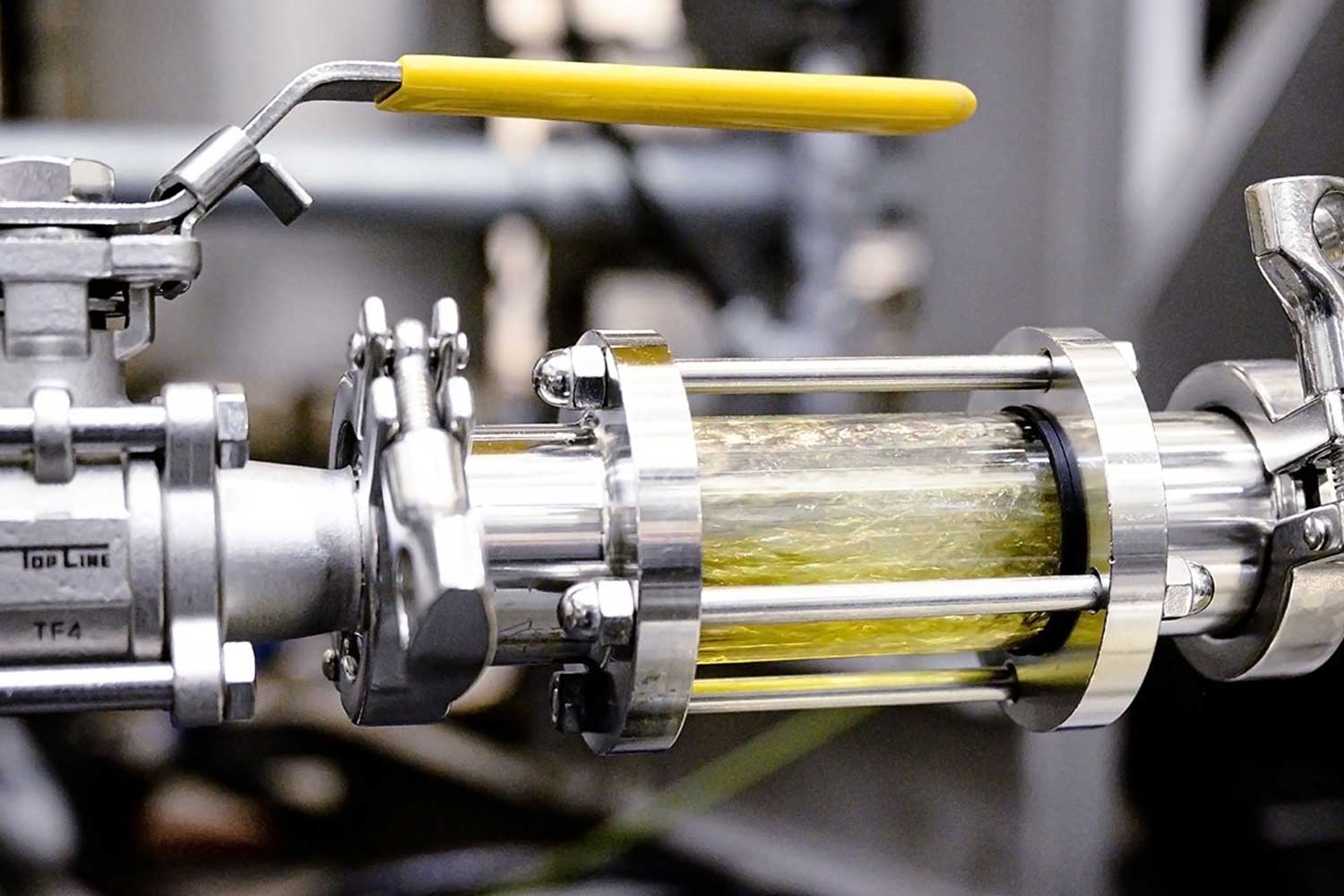

How does accelerated solvent extraction work?

Microwaves are electromagnetic waves with a wavelength between 1mm-1m (frequency between 3×108~3x 1011Hz). The traditional heating method is to first heat the surface of the object, and then the heat energy is transferred from the surface to the inside, which is the so-called “external heating”. Microwave heating is a kind of “internal heating” which is a kind of “internal heating”, which is a kind of “internal heating”, which is a kind of “internal heating” is caused by the material that absorbs microwave energy and produces friction and vibration between its internal molecules. Microwave-assisted extraction is the use of microwave heating to accelerate the dissolution of the target extract in the solid by the solvent, so as to achieve rapid and efficient extraction

Selection of Microwave Assisted Extraction (MAE) Conditions

Extraction solvent

The choice of solvent is crucial. The components extracted by the microwave should be microwave-sensitive substances with a certain polarity. The solvent selected for microwave extraction must be transparent or translucent to microwaves, that is, a solvent with a small dielectric constant (8-28) must be selected, and the solvent must have a strong dissolving ability for the target component, which will interfere with the subsequent operation of the extracted component less. In this way, the microwave can penetrate completely or most of the extractant and be absorbed by the extract to achieve the purpose of extraction.

Common solvents used for MAE are methanol, ethanol, acetone, acetic acid, dichloromethane, benzene, toluene, n-hexane, and inorganic acids such as nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, and hexane-acetone, dichloromethane-methanol, Water-toluene, and other mixed solvents.

For the same material, the extraction effects of different extractants are often quite different.

In addition, the water content of the material has a great relationship with the absorption of microwave energy. If the material is dried and does not contain moisture, then a part of the extraction medium that absorbs microwave energy should be selected, and the material should be impregnated with this medium and placed in a microwave field for radiant heating and extraction will occur at the same time. The method of re-wetting the material can also be adapted to make it have enough moisture to effectively absorb the required microwave energy.

Microwave power and extraction time

Microwave extraction frequency, power, and time have obvious effects on extraction efficiency.

Commonly used frequencies are 9.15×102MHz and 2.45×103MHz.

The level of microwave power has a greater impact on the measurement results. When the time is fixed, the higher the power, the higher the extraction efficiency and the more complete the extraction. However, if it exceeds a certain limit, the pressure of the extraction system will rise to the extent that the safety valve of the container is flushed, and the solution will spill, causing errors or even accidents.

The determination of microwave energy or microwave dose is based on the most effective extraction of the required active ingredients. Waves of any wavelength in the microwave band can be absorbed by the ingredients in the material to varying degrees.

When the selected microwave power is in the range of 200~1000W, the change in extraction time is small. The microwave extraction time is related to the sample volume, solvent volume, and heating power of the test substance, and is generally between 10 and 100 seconds.

In the extraction process, the required extraction temperature is generally reached within 1~2min from the beginning of heating. The length of the extraction time is also related to the water content in the material because water can effectively absorb microwave energy, and drier materials require a longer irradiation time.

What is solvent free microwave extraction?

Solvent-free microwave extraction (SFME) is a combination of microwave heating and dry distillation, performed at atmospheric pressure without adding any solvent or water. Isolation and concentration of volatile compounds are performed in a single stage. SOME has been compared with a conventional technique, hydro-distillation (HD), for the extraction of essential oil from three aromatic herbs: basil (Ocimum basilicum L.), garden mint (Mentha crispa L.), and thyme (Thymus vulgaris L.). The essential oils extracted by SFME for 30min were quantitatively (yield) and qualitatively (aromatic profile) similar to those obtained by conventional hydro-distillation for 4.5 h. The SFME method yields an essential oil with higher amounts of more valuable oxygenated compounds, and allows substantial savings of costs, in terms of time, energy, and plant material. SFME is a green technology and appears as a good alternative for the extraction of essential oils from aromatic plants.

What is ultrasound-assisted extraction in UAE?

One of the important steps when studying medical plants is extraction. Currently, some modifications were done based on conventional methods in the processing of medicinal products, which are aimed at increasing yield at a lower cost.

Ultrasonic-assisted extraction (UAE) is one of the modifications, where the extraction process is assisted with the usage of ultrasound waves. Two major factors that increase the efficiency of using ultrasound waves are cell disruption and effective mass transfer.

UAE was shown to be a viable alternative to the conventional extraction procedure for the higher extraction yield of thymol as compared to conventional methods. UAE is also able to shorten the duration of extraction to achieve optimum extraction efficiency.