What is Solid Phase Microextraction

Solid-phase microextraction (SPME) is a new technology for sample analysis pretreatment that has emerged internationally in recent years.

Who invented solid phase microextraction?

In 1990, it was pioneered by Arthur and Pawliszyn of Waterloo University in Canada. In 1993, Supelco Company of the United States launched a commercial solid-phase microextraction device. In 1994, it won the Pittsburgh Analytical Instrument Conference Award.

What is solid phase microextraction used for?

Initially, researchers applied this technology to environmental chemical analysis (water, soil, atmosphere, etc.). With the deepening of research and the continuous improvement of the method itself and the improvement of the device, it has gradually expanded to food, natural products, medicine and health, clinical Chemistry, Biochemistry, Toxicology, and Forensic Science.

Solid-phase microextraction overcomes the defects of traditional sample pretreatment technology, integrating sampling, extraction, concentration, and sample injection, which greatly speeds up the speed of analysis and detection. Its remarkable technical advantages are being widely concerned by analysts in the environmental, food, and pharmaceutical industries, and are being vigorously promoted and applied.

What is the difference between SPE and SPME?

Solid-phase extraction is one of the best sample pretreatment methods, with a series of advantages such as simplicity, low cost, and easy automation.

While solid-phase microextraction is developed on the basis of solid-phase extraction, it retains all its advantages and abandons the disadvantages of column packing and solvent desorption.

Solid-phase microextraction technology is based on the use of fused silica fibers coated with a stationary phase to adsorb and enrich the analyte in the sample.

Among them, sorbent extraction technology started in 1983. Its biggest feature is that it can concentrate the analyte while extracting. The most commonly used solid-phase extraction (SPE) technology is to fill the sorbent in a short tube, when the sample solution or As the gas passes through, the analytes are adsorbed and extracted, and then various analytes are selectively eluted with different solvents.

Solid phase microextraction principle

Using fused silica optical fiber or other materials as the matrix support, adopting the characteristics of “similar compatibility”, coating the surface of the polymer stationary phase thin layer with different properties, and extracting the object to be tested by direct or headspace methods, Enrichment, injection, and analysis. Then, the fiber-enriched with the analyte is directly transferred to the instrument (GC or HPLC), desorbed in a certain way (usually thermal desorption, or solvent desorption), and then separated and analyzed.

The principle of solid-phase microextraction (SPME) is different from that of solid-phase extraction. Solid-phase microextraction does not extract all the analytes. The principle is based on the equilibrium distribution of analytes between the stationary phase and the aqueous phase. superior.

Features

It integrates sampling, extraction, concentration, and injection, with convenient operation, short time-consuming, and fast and efficient determination.

Without any organic solvent, it is solid phase extraction in the true sense, avoiding secondary pollution to the environment.

The instrument is simple, does not require auxiliary equipment, is suitable for on-site analysis, and is easy to operate.

High sensitivity, and ultra-trace analysis can be achieved, and detection at the nanogram per gram level can be achieved.

How does solid phase microextraction work?

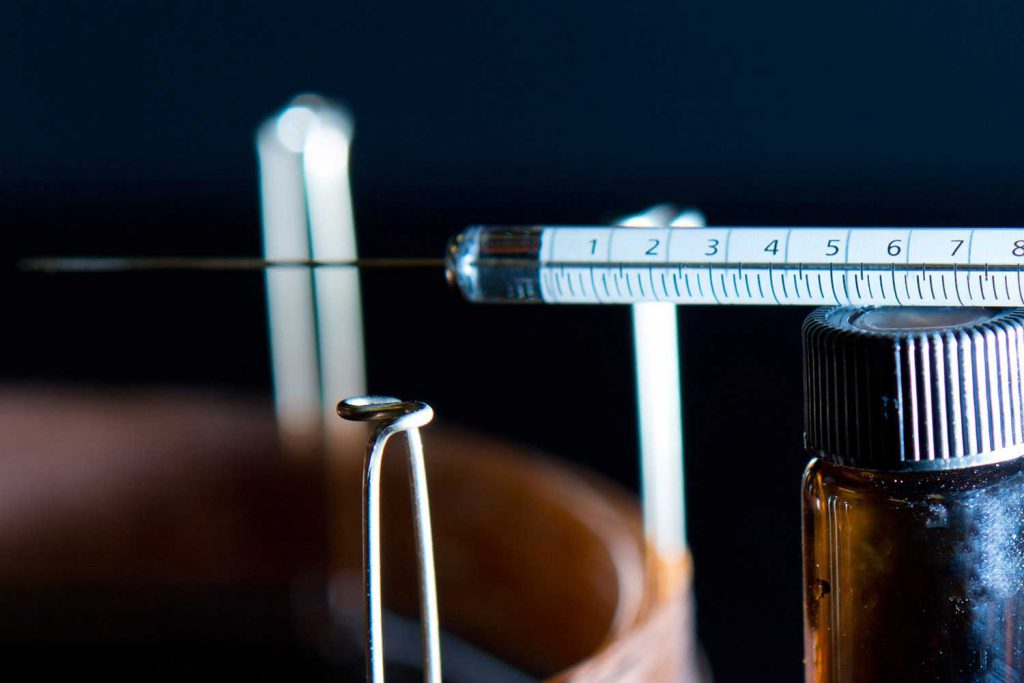

Solid-phase microextraction requires only a solid-phase microextraction device similar to a sampler to complete all pretreatment and sample injection. There is a telescopic rod in the needle of the device, and a fused silica fiber is connected to it. The surface of the device is coated with a chromatographic stationary phase. Generally, the fused silica fiber is hidden in the needle. stretch out.

When analyzing, put the sample into a special container for solid phase micro-acquisition with a diaphragm plug. If it is necessary to add inorganic salts, derivatizing agents or adjust the pH at the same time, it can also be heated or stirred with a magnetic rotor.

Immerse the fiber tip in the sample solution or headspace gas for a period of time, while stirring the solution to speed up the equilibrium between the two phases. After equilibrium, the fiber tip is taken out and inserted into the gas chromatography vaporization chamber to thermally desorb the adsorbed substances on the coating.

After the extract is desorbed in the vaporization chamber, it is introduced into the chromatographic column by the mobile phase to complete the whole process of extraction, separation and concentration.

Solid phase microextraction working steps

Solid phase microextraction is divided into two steps:

The first step is extraction, insert the needle into the sample container, push out the quartz fiber to extract the analytical components in the sample.

The second step is to insert the needle into the chromatographic injector during the injection process, push out the quartz fiber, and complete the steps of desorption and chromatographic analysis.

Three extraction modes

There are three basic extraction modes for solid phase microextraction: Direct Extraction SPME, Headspace SPME and membrane-protected SPME.

Solid phase microextraction direct extraction

In the direct extraction method, the quartz fibers coated with the extraction stationary phase are inserted directly into the sample matrix, and the target components are directly transferred from the sample matrix to the extraction stationary phase. During laboratory operations, agitation methods are commonly used to accelerate the diffusion of analytical components from the sample matrix to the edges of the extraction stationary phase.

For gas samples, natural convection of the gas is sufficient to accelerate the equilibrium of the analytical components between the two phases. However, for water samples, the diffusion rate of components in water is 3-4 orders of magnitude lower than that in gas, so an effective mixing technique is required to achieve rapid diffusion of components in the sample.

The more commonly used mixing techniques are: increasing the flow rate of the sample, shaking the extraction fiber head or sample container, rotor stirring and ultrasound.

These mixing techniques, on the one hand, accelerate the diffusion rate of the components in the bulk sample matrix, and on the other hand reduce the so-called “depletion zone” effect caused by the protective sheath of a liquid film formed on the outer wall of the stationary phase.

Solid phase microextraction headspace extraction

In headspace extraction mode, the extraction process can be divided into two steps:

- The analyzed component first diffuses and penetrates from the liquid phase to the gas phase;

- The analyzed components are transferred from the gas phase to the extraction stationary phase. This modification avoids contamination of the extraction stationary phase with high molecular weight and nonvolatile substances in some sample matrices such as human secretions or urine.

In this extraction process, the extraction speed of step 2 is generally much greater than the diffusion speed of step 1, so step 1 becomes the control step of extraction.

Therefore, volatile components have a much faster extraction rate than semi-volatile components. In fact, for volatile components, under the same sample mixing conditions, the equilibration time of headspace extraction is much shorter than that of direct extraction.

Membrane protection extraction

The main purpose of membrane protection SPME is to protect the extraction stationary phase from damage when analyzing very dirty samples. Compared with headspace extraction SPME, this method is more favorable for the extraction and enrichment of less volatile components.

In addition, the protective film made of special materials provides a certain selectivity to the extraction process.

Factors Affecting Solid Phase Microextraction

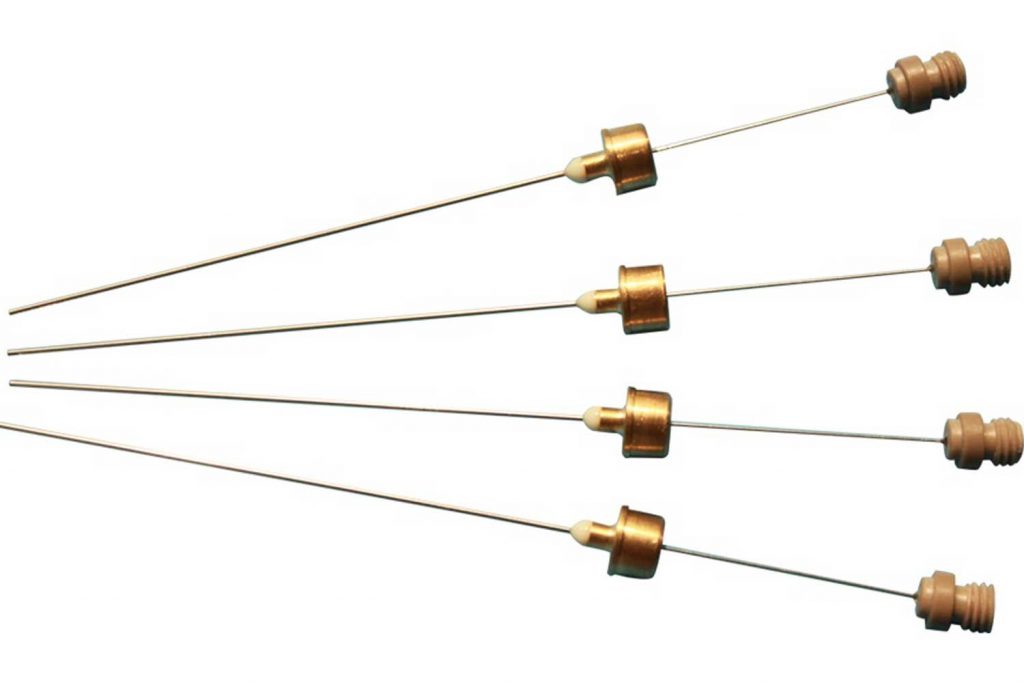

Type and film thickness of extraction head

At present, there are seven types of commercial extraction heads, and the stationary phase can be coated on the quartz fiber in four forms: bonded, non-bonded, partially cross-linked and highly cross-linked.

Coating

The stability of coatings in organic solvents decreases in the following order: bonded > partially crosslinked > non-bonded. The polarity of the coating has a great influence on the selection and extraction of the analyte. According to the principle of “similar compatibility”, the non-polar coating is conducive to the separation of non-polar or less polar organic substances; The separation effect of sexual organic matter is better.

Coating thickness

In addition, the thickness of the coating also affects the adsorption capacity and equilibration time of the analyte. Thick coatings are suitable for volatile compounds, while thin coatings are more advantageous for the extraction of macromolecules or semi-volatile compounds. , the thicker the coating, the greater the adsorption capacity, which is beneficial to expand the linear range of the method and improve the sensitivity of the method, but it takes longer to reach equilibrium, however, the thickness and length of the extraction coating are limited by the extraction fiber support material , For example, the commonly used quartz fiber material is relatively brittle, and the types and quantities of polymer stationary phase films that can be coated on its surface are limited.

Specifically, the extraction and enrichment of organic compounds by the polymer stationary phase coating is a dynamic equilibrium process, and the coating should have a strong selection of organic molecules.

Extraction temperature

The extraction temperature has a dual effect on the solid-phase microextraction. The increase of the temperature can speed up the molecular diffusion rate of the analyte, which is conducive to reaching equilibrium as soon as possible. The adsorption capacity of HS-SPME is reduced, which reduces the sensitivity. For HS-SPME, there is also the superfluous temperature. Generally speaking, a low superficial temperature is conducive to adsorption.

Extraction time

The extraction time is affected by many aspects, including the type and film thickness of the extraction head, the adsorption capacity, the distribution coefficient of the analyte between the substrate and the coating, the diffusion rate, and the amount of the substrate. In general, substances with small partition coefficients require longer extraction times. In order to improve the reproducibility of the experiment, the same extraction time should be selected in general experiments.

Salt effect and pH effect

The two are essentially the same, both affect the ionic strength of the matrix, thereby affecting the partition coefficient of the analyte between the matrix and the coating. The salt effect is divided into two types: “salting dissolution” and “salting out”. Salting out is due to the increase of ionic strength, which increases the amount of analyte dissolved in the matrix, which is not conducive to the extraction; The K value increases, thereby improving the extraction efficiency. Zhong Haiyan and others found that in the process of flavor extraction, the extraction effect can be improved, especially for compounds with larger molecular weights. The effect of pH is to change the solubility of the analyte in the matrix by adjusting the pH to affect the ionic strength in the solution.

Influence of stirring efficiency

Agitation can speed up matrix transfer, thereby reducing extraction time, especially for high molecular weight and high diffusion coefficient components. Commonly used stirring methods include ultrasonic stirring, electromagnetic stirring, and high-speed homogenization. When using stirring methods, attention must be paid to the uniformity of stirring. Uneven stirring is less accurate than the measurement without stirring.

Desorption temperature

Desorption temperature is another factor that affects SPE. At a certain temperature, the longer the desorption time is, the more sufficient the desorption will be. If the desorption is insufficient, it may cause pollution to the next extraction. In a certain period of time, the higher the temperature, the better the desorption. However, if the temperature is too high, the life of the extracted fibers will be shortened. Generally, the aging temperature of the extraction head is often selected as the desorption temperature.

Applications of Solid Phase Microextraction

Environmental sample testing

The earliest application of solid-phase microextraction was in the detection of environmental samples, and it still plays a huge role in the analysis of trace elements in environmental samples.

It is widely used in solid (such as sediment, soil, etc.), liquid (drinking water and wastewater, etc.) and gaseous (air, fragrance and waste gas, etc.) sample analysis.

Solid sample

The applications in solid samples include the detection of butyltin compounds in sediment, organochlorine and nitro compounds in soil and sediment, fatty acid detergent components in sludge and other sediments, and benzene series and their halogens in sludge. Substitutes and other organic compounds detection and so on.

Water body

The applications in water bodies include the analysis of 1-naphthol, 2,4-dinitrophenol and other benzene series compounds in environmental water samples, the analysis of profenofos, gasoline, alcohols, tin, arsenic, lead and other organic metals and Detection of other inorganic metal ions, organophosphorus and organochlorine pesticides, herbicides, methylmercury, amines, polycyclic aromatic hydrocarbons, hydroxyl compounds, and alkanes, aliphatic hydrocarbons, alcohols, esters and volatile aromatic compounds in wastewater etc.

Gaseous

The application in gaseous samples includes the detection of amines and fatty acids in the gas, and the use with diffusion tubes, and is used in volatile organic compounds (benzene, methylcyclohexane, toluene, tetrachloroethylene, chlorobenzene, ethylbenzene) , p-xylene, styrene, nonane and cumene, etc.) detection and detection of petroleum hydrocarbon compounds.

Food analysis

Due to the characteristics of solid-phase microextraction, it was applied to the analysis of trace components in food soon after the technology appeared, and it has been widely developed in the world.

Such as the analysis of organic volatiles in edible vinegar, the analysis of benzoyl aromatic compounds in liquor, the detection of dichlorvos content in liquor, the detection of mustard flavor, the volatile aromatic compounds in fruits, the volatile organic acids in potatoes, Aromatic compounds such as nitroaniline in prosciutto and detection of volatile organic compounds in sunflower, etc.

Drug testing

Solid-phase microextraction technology has developed rapidly in drug analysis and drug testing, and is gradually becoming an indispensable detection method in physiology, pathology and toxicology.

Such as the analysis of antihistamine compounds in human body fluids, and the detection of domeridine content in blood and urine, the detection of some alkaloids in urine and the detection of dichlorobenzene isomers in urine, and the detection of cyanide in blood , Detection of steroids, phenolazine and phenolic compounds in serum, detection of organophosphorus pesticides and benzene compounds in body fluids, detection of cannabidiol and corticosteroids in saliva and acetone in the human respiratory system, etc.

Other areas

According to the characteristics of solid-phase microextraction, this technology is used in more and more practical production and life fields, such as the detection of pesticide residues and azo dyes in textiles, the detection of residual organophosphorus pesticides in vegetables and In the detection of carbon tetrachloride in shampoo, it has also been widely used in the tobacco industry, such as the analysis of flavors and flavor components in finished cigarettes, the aroma components in cigarette cut tobacco, and the analysis of organic acid content in tobacco leaves .