Extraction Method of Pigment in Grape Skin One

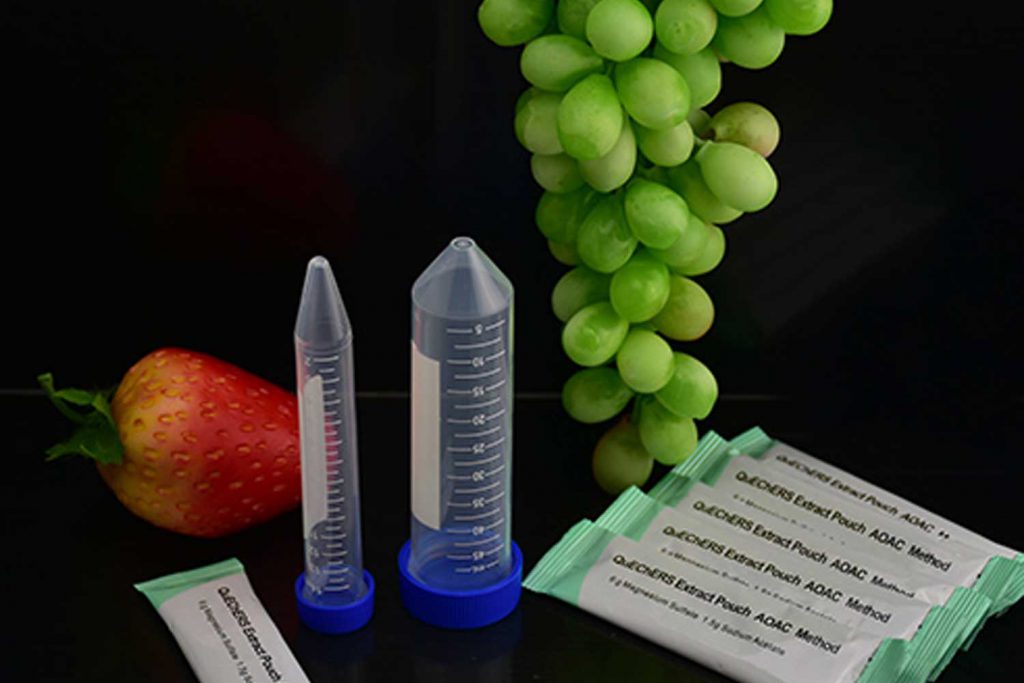

Reagent

Distilled water, ethanol, citric acid

Equipment

Centrifuge, enamel glass reactor, Buchner funnel, constant temperature water bath, vacuum concentration device, spray dryer, etc.

Extraction steps

Raw material→pretreatment→leaching (Solid-Liquid Extraction)→filtration→concentration→drying→pigment finished product.

Extraction process

Raw material

Made from fresh grape skins

Preprocessing

After the grape skin residue was washed with clean water, it was dehydrated with a centrifuge, and the dehydrated product was placed in an enamel glass reactor.

Leaching

Add 2 times the mass of ethanol with a concentration of 70% to the reactor, and add an appropriate amount of citric acid (or tartaric acid) while stirring at room temperature to adjust the pH, so that the pH of the extract is about 3.0, and the constant temperature mold is stirred for 4~5h, get the extract

Lilter

After the extract is centrifuged by a centrifuge, it is filtered with double-layer gauze or Buchner funnel, the filtrate is collected and the filter residue is discarded.

concentrate. The filtrate was concentrated under reduced pressure below 50°C to form a gum.

Dry

The colloid obtained by concentration is spray-dried to obtain the finished product of grape skin pigment.

Extraction Method of Pigment in Grape Skin Two

Reagent

Distilled water, ethanol, hydrochloric acid, quartz sand, and lead acetate.

Equipment

Mortar, vacuum filtration device, vacuum drying device, etc.

Process steps

Raw material→pretreatment→leaching→filtration→drying→purification→finished product.

Extraction process

- Raw materials. Made from the skins of fresh Kyoho grapes.

- Pretreatment. Clean the grapes, peel the peels and put them in a mortar, add a small amount of distilled water (adjust pH=1) or ethanol (adjust pH=3), and add a little quartz sand to grind, and grind the grape skins into a paste.

- Leaching. Add 2 times the amount of acidified water (pH=1) or acidified ethanol (pH=3) to the grape skin pulp and continuously stir to extract the pigment to obtain the extract.

- Filter. The extract was filtered through filter paper under reduced pressure to obtain the crude extract of grape skin pigment.

- Dry. The crude extract of grape skin pigment was dried under reduced pressure to form a solid.

- Purification. Add a small amount of distilled water to the solid to dissolve, and then add 50% lead acetate to stir, and the pigmenting material will form a precipitate. The precipitate was collected by filtration, and then the precipitate was dissolved in 8% hydrochloride water or hydrochloride ethanol to form a white precipitate of lead chloride. The white precipitate was removed by filtration, and a red solution of grape skin pigment with high purity was obtained.

Physical and chemical properties of Grape Skin Pigments

The main component of grape skin pigment is anthocyanin. The pigment contained in grape skin is red when pH=3.0, purple when pH=4.0, and blue when alkaline, and its stability increases with the decrease of pH. increase. Therefore, it can be extracted and separated from the grape skin with acidified ethanol or water. In an acidic medium, grape skin pigment has several tautomers with different pHs. The increase of acidity is beneficial to the extraction of pigment, but too high acidity will reduce the extraction yield of pigment. Experiments show that adjusting the extraction acidity in the range of pH 3-4 can not only have a higher extraction yield of pigment but also obtain pure and bright natural purple pigment of grape skin.

Application of Grape Skin Pigments

Grape skin pigments are often used in the coloring of high-grade acidic foods and can be used as colorants for fruit drinks, carbonated drinks, alcoholic beverages, cakes, jams, etc. It is characterized by strong tinting strength and good effect. The dosage in liquid products such as beverages and wine jams is 0.1%~0.3%, the dosage in powder food is 0.05%~0.2%, and the dosage in ice cream is 0.002%~0.2%.