What is the supercritical CO2 extraction method?

Supercritical CO2 Fluid Extraction (SCFE) uses high-pressure, high-density supercritical fluid (SCF) as a solvent to dissolve the required components from liquid or solid, and then uses methods such as temperature rise, pressure reduction, absorption (adsorption), etc. An operation that separates the solvent from the extracted components, ultimately yielding the desired pure components.

The basic principle of the supercritical CO2 extraction method

The SCF CO2 extraction method is carried out using the effect of pressure and temperature on the dissolving ability of SCF.

When the gas is in a supercritical state, it becomes a single-phase state with properties between liquid and gas, with a density similar to that of liquid, although the viscosity is higher than that of gas but significantly lower than that of liquid, and the diffusion coefficient is 10-100 times that of liquid. Therefore, it has good permeability and strong dissolving ability to the material and can extract some components in the material.

In the supercritical state, contacting the supercritical CO2 fluid with the substance to be separated can make it selectively and sequentially extract the components with different polarities, different boiling points, or different molecular weights.

The density and dielectric constant of supercritical CO2 fluid increase with the increase of the pressure of the closed system, and the polarity increases. Of course, the extract obtained corresponding to each pressure range cannot be single, but the optimal proportion of mixed components can be obtained by controlling the conditions. Then, the supercritical CO2 fluid is turned into ordinary gas by means of decompression and heating, and the extracted substances are automatically precipitated, so as to achieve the purpose of separation and purification, which is the basic principle of SCF extraction.

Is CO2 extraction better than cold-pressed?

The CO2 extraction method is best because oxygen-free environments and low temperatures are particularly important when extracting fragile oils like Rosehip.

By keeping temperatures low and extracting all the ‘active’ components, we’re able to preserve and protect the complete botanical, skin-loving properties of the Rosehip.

The CO2 extraction method process delivers twice the regenerative sterols and five times more of those carotenoids than your average Rosehip seed oil. It also means it lasts four times longer in your bathroom cabinet!

The CO2 extraction method also leaves absolutely no solvent residues, so the final oil is impeccably pure. The low temperature and lack of waste streams/emissions make it an extremely environmentally friendly process, too!

Is CO2 extraction safe?

CO2 is a naturally occurring compound. It exists all around us and our bodies produce it.

As far as non-polar solvents are concerned, CO2 is among the safest. In fact, the FDA has labeled CO2 safe for industrial extractions, making it a much less controversial solvent than petroleum-based hydrocarbons such as butane or propane.

The conditions that allow CO2 to change from a fluid state to a supercritical state can occur without having to exceed temperatures above 90°F, meaning there is less risk of compromising the natural volatile compounds found in cannabis.

Why is CO2 Extraction Better than Butane / Solvent Extraction?

Butane / solvent extraction method

Butane as the solvent extraction, you must factor in the cost of ventilation, or a protected explosion-proof environment. Although the installation can pose hazards, closed-loop systems significantly decrease operating risks for owners.

Even with proper training, equipment, and environment, BHO extraction systems can be dangerous. In 2014 in the US, there were 3 BHO extraction explosions, 30 injuries, and 32 explosion-related deaths. This is in comparison to 12 explosions and 18 injuries in 2013.

Supercritical CO2 extraction method

Despite having a costlier initial setup, CO2 is cheaper than butane, making the system more cost-effective to run. As CO2 is produced by natural means, if it is released back to the environment it does not have a negative impact on the atmosphere, making it a much safer and environmentally responsible choice than BHO. SCE does not require the same explosion-proof facility setup that BHO does, or safety equipment and training for operators to work with.

CO2 is also non-toxic- it is a natural waste product from human bodies and fermentation. Due to this and its gaseous state at atmospheric pressure, all extracts made from SCE are pure and completely clean of any potentially toxic or heavy metal residues that can be left behind in BHO.

CO2 has solvency power at a much lower set of extraction parameters in comparison to other solvents and therefore can extract compounds that usually are degraded at higher temperatures or pressures such as terpenes. Carbon dioxide extracts are accordingly stronger in aroma and flavor and bear a profile that most closely resembles the original plant. These extracts are preferred in the market as their scent and flavoring are highly valued by purveyors.

Why use CO2 extraction better?

Extraction and separation in one

When the supercritical CO2 fluid saturated with dissolved substances flows through the separator, it is immediately separated from the extracted substance into two phases (gas-liquid separation) due to the pressure drop. There is no phase change process of the material, and no solvent recovery is required. Easy to operate. Not only the extraction efficiency is high, but also the energy consumption is less and the cost is saved.

High extraction efficiency and easy process control

For example, small changes in temperature and pressure of CO2 near the critical point will cause significant changes in its density, thereby causing changes in the solubility of the substance to be extracted. The extraction purpose can be achieved by controlling the temperature or pressure. When the pressure is fixed, the substances can be separated by changing the temperature; on the contrary, when the temperature is fixed, reducing the pressure can separate the extracts. Therefore, the process flow is short, and time-consuming, no pollution to the environment, and the extraction fluid can be recycled, which truly realizes the greening of the production process.

Low extraction temperature

It can effectively prevent the oxidation and dissipation of heat-sensitive components, preserve the effective components well without damage and no secondary biochemical, and can extract substances with a high boiling point, low volatility, and easy pyrolysis below their boiling temperature. It is especially suitable for the extraction of heat-sensitive and easily oxidative decomposition components.

Commonly used SCF has low toxicity and no solvent residue

For example, the critical CO2 fluid is a gas under normal conditions, non-toxic, and there is no solvent residue after separation from the extraction components, which effectively avoids the toxicity of the residual solvent to the human body and the pollution to the environment under the traditional extraction conditions.

The polarity of supercritical fluids can be changed

Under certain temperature conditions, as long as the pressure is changed or a suitable entrainer (co-solvent) is added, substances of different polarities can be extracted, and the selection range is wide.

In the extraction of polar substances, by changing the process conditions, especially the addition and use of various entertainers, the application of supercritical CO2 extraction has been greatly broadened, and the extraction of many polar substances has become possible.

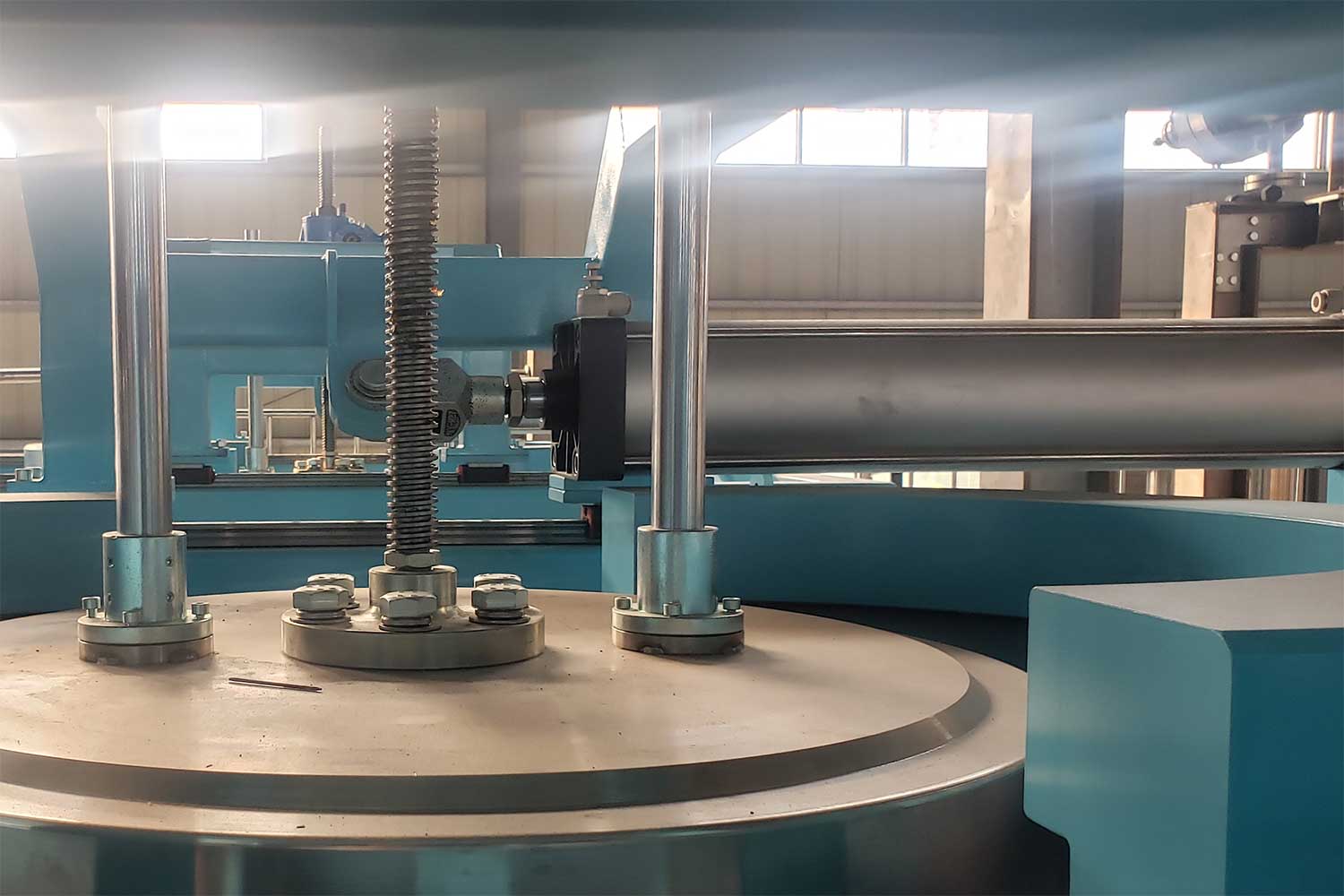

CO2 Extraction Process

- Load extraction vessel with biomass.

- Bring each vessel to working pressure using CO2 from supply cylinders.

- Create supercritical CO2 fluid.

- Alter pressure and temperature, depending on what’s being extracted and the goals of the extraction.

- Pass the supercritical CO2 through an extractor containing the plant matter itself.

- In Extraction Vessel, compounds are pulled from biomass into solution.

- Solvent (CO2) is boiled out of solution in Separator 1.

- Evaporated CO2 is condensed into liquid and stored in Accumulator.

- Pass the new solution through a separator to quickly and easily remove (and recycle!) the liquid CO2.

- After the allotted run time, the system is depressurized by releasing CO2 through Separator 2 or 3. (Popular CO2 machines are often equipped with 3 separators: Waxes separation and Light oil separation in 1st separator. Light oil separation in 2nd separator. To trap lightest and volatile compounds in 3rd separator.)

In the video on the left is our entire process of extracting roses.

The turmeric essential oil in the picture is the extract we obtained in the experiment. The color is transparent and clear, and the smell is pure. Like other essential oils obtained by the CO2 extraction process, no special treatment is required. For example, the best-selling Ganoderma lucidum robe oil in China.

Note: In the CO2 extraction process, CO2 is recycled in the machine, and the large CO2 extraction machine is also equipped with a CO2 recovery system to save production costs. Of course, some gas will be lost, about one-third of the weight of the extract.